The Challenge: Rescuing a Stalled Multi-Million Euro Strategy

In late 2017, a Chief Product Officer joined Omniva during a critical organizational crisis. Estonia's state-owned postal and logistics company faced interconnected challenges threatening both immediate operations and long-term strategic position.

The Immediate Crisis

Stalled Technology Transformation

An ambitious multi-million euro development project aimed to replace Omniva's entire technology stack: parcel machine platform, sorting platform, hardware, courier management systems, and geoinformation system. Despite significant investment, the project had reached an impasse—millions spent with no tangible results.

Immovable Deadline Pressure

A new logistics center on Tartu Road was under construction, with concrete already poured. The facility required fully functional information systems integrated with existing infrastructure. The opening date was fixed, creating public accountability pressure typical of state-owned enterprises.

Vendor Dependency Constraint

Omniva's parcel machine network relied entirely on a Polish firm's full-service solution. This dependency severely limited innovation capacity, particularly problematic given the strategic importance of parcel machines to Omniva's competitive position. With e-commerce growing approximately 30% annually, the inability to rapidly expand and adapt the parcel machine network risked market share loss to competitors like Itella and DPD.

Organizational Complexity

An analysis revealed over 200 ongoing projects, goals, and constraints across the organization. Strategy had become fragmented, focus diffused. Traditional project-driven management approaches weren't delivering results under the complexity and urgency the situation demanded.

The Systematic Response: Framework Implementation

Rather than treating these as separate technical problems, we approached the transformation systematically, implementing product management principles adapted for state enterprise constraints.

Product Office Creation

We established a Product Office as the coordination hub for transformation—not to create bureaucracy, but to enable systematic prioritization and resource allocation across competing initiatives.

Dual PM Role on Critical Initiatives: On the most critical projects—particularly parcel machine development and new logistics center systems—CPO served directly as Product Manager. This wasn't about centralizing control, but about ensuring coordination patterns were established that could later be transferred to internal teams.

Cross-Functional Product Teams: We reorganized work around products rather than traditional functional silos. Teams owned outcomes (functional parcel machines, operational logistics center systems) rather than completing assigned tasks. This required clear decision rights mapping—who decides what, and when does coordination require escalation.

Technology Panel Establishment

With multiple technical initiatives running simultaneously, we created a Technology Panel as a lightweight governance mechanism. Rather than centralized control, this provided architectural consistency while enabling team autonomy.

Systematic Decision Framework: The Panel established clear criteria for technical decisions: compatibility requirements, scalability considerations, vendor independence principles. Teams could move quickly within these guardrails without constant approval cycles.

Measurement Systems Enabling Coordination

A critical element of the systematic transformation was building data infrastructure that made organizational reality visible. This wasn't just about creating dashboards—it required fundamentally rethinking how information flowed through the organization.

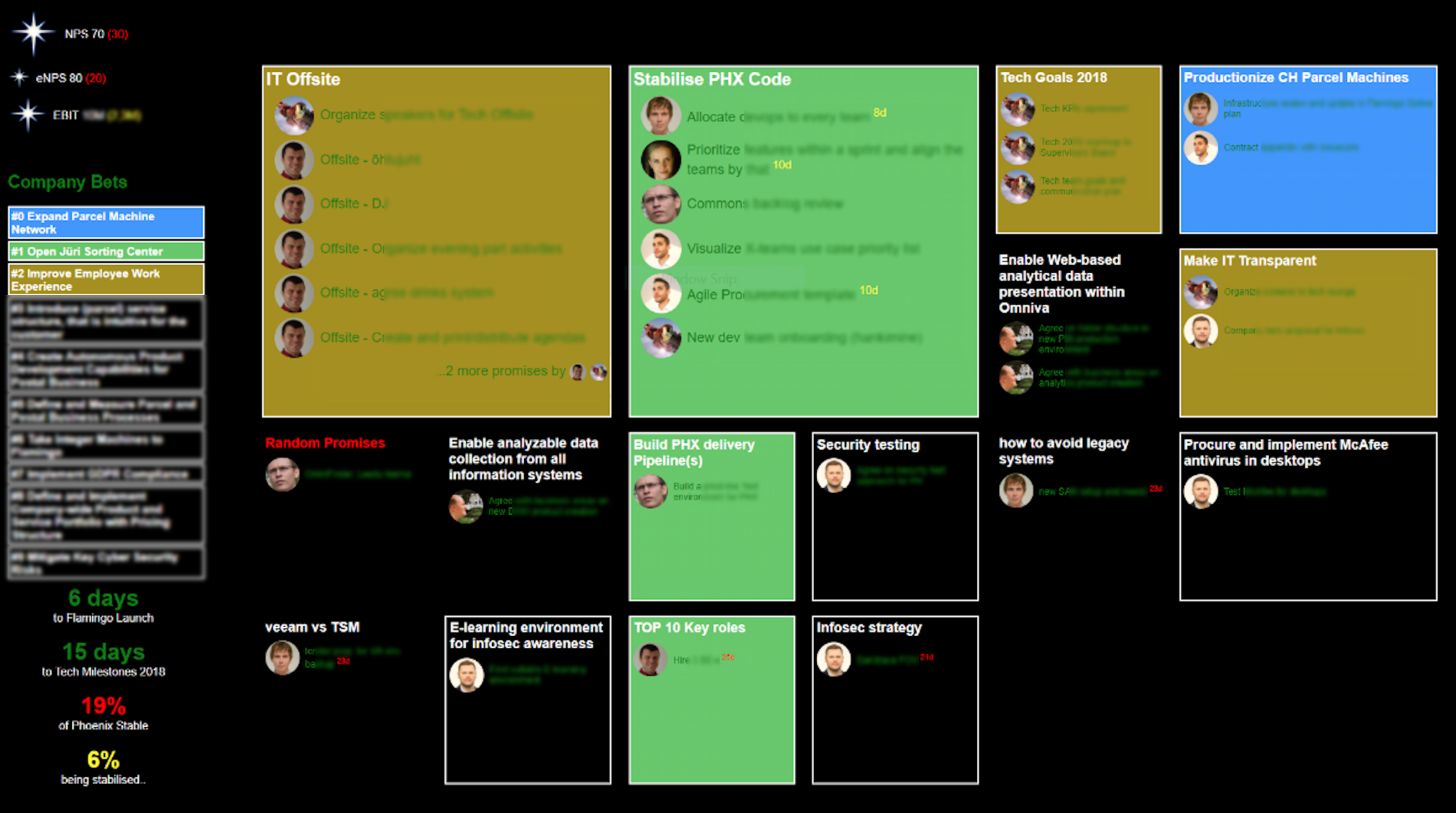

Visual Management Platform: We created a centralized dashboard that brought together real-time information about team activities, progress, and resource allocation. But the technical dashboard was only half the solution. The real transformation required reorganizing workflows so that people entered the right data, at the right time, in the right way. This meant changing how teams tracked work, reported progress, and documented decisions.

The dashboard wasn't a passive reporting tool—it was designed to make strategic alignment visible. Teams could see how their activities connected to strategic objectives, where resources were actually being deployed versus where they were planned, and which initiatives were creating the most value. This transparency fundamentally changed how prioritization decisions were made, shifting from hierarchical opinion to evidence-based discussion.

IT Bottleneck Visualization: One powerful application was making IT coordination problems immediately visible. We visualized project team interdependencies and tracked resolution times for blocking issues. When a team was waiting on another team, this became instantly apparent to leadership. The most painful bottlenecks—like dependencies between teams that had no regular communication channels—surfaced quickly and forced systematic resolution rather than letting projects stall indefinitely.

This visual system created organizational accountability through transparency. Problems that previously festered in status reports now demanded attention because they were visible to everyone. Teams naturally began coordinating more effectively because the cost of poor coordination was no longer hidden.

Resource Allocation Reality: Perhaps most importantly, the dashboard showed where resources actually went versus where strategic plans assumed they would go. This enabled informed decisions about resource reallocation and activity prioritization. When leadership could see that 70% of development capacity was consumed by maintenance and support rather than strategic initiatives, it forced honest conversations about trade-offs and priorities.

This data product approach—treating internal management information as a product serving internal customers—proved essential for coordinating complex transformation under fixed deadline pressure. The systematic visibility enabled rapid problem identification and resolution that would have otherwise required lengthy status meetings and report compilation.

Incremental Delivery Under Fixed Constraints

With the logistics center opening date immovable, we applied counterintuitive principles: start with minimal viable functionality, then enhance systematically based on operational reality.

Systematic Risk Reduction: Rather than attempting comprehensive requirements gathering upfront, we focused on the minimum systems needed for day-one operations, then planned systematic expansion. This felt slower initially but provided much higher confidence in meeting the critical deadline.

Integration Discipline: With parcel machines, sorting systems, and logistics center systems all being developed simultaneously, we established clear interface contracts between teams. Regular integration checkpoints prevented the "big bang" failures typical of complex system implementations.

The Outcomes: Systematic Delivery Under Pressure

The systematic approach enabled Omniva to achieve what had seemed impossible when the transformation began.

Strategic Implementation Results

Critical Deliverables Achieved

Logistics Center Launch: The new Tartu Road facility opened on schedule with fully functional integrated systems. This wasn't luck—it was the result of systematic incremental delivery and continuous integration discipline.

Parcel Machine Independence: Omniva successfully transitioned to producing its own parcel machines, breaking vendor dependency. Hundreds of new machines were deployed on proprietary infrastructure, creating competitive barriers that competitors couldn't simply purchase from vendors.

Legacy System Transition: The organization successfully developed and deployed a new information system while simultaneously maintaining operations and eventually shutting down previous generation systems. This complex transition succeeded because of systematic coordination and transparent progress tracking.

Organizational Capability Development

Agile Methodology Adoption: The implementation of systematic product management principles enabled faster problem identification and resolution. Issues that previously stalled projects for extended periods now surfaced quickly with clear resolution paths and accountability.

Product-Driven Culture Shift: Teams shifted from project execution mindset to product ownership. This change—from "completing assigned work" to "delivering customer value"—persisted beyond the transformation period and enabled ongoing organizational evolution.

Competitive Infrastructure: Beyond immediate deliverables, Omniva built differentiated capabilities. The proprietary parcel machine infrastructure, combined with systematic development processes, created sustainable competitive advantages that couldn't be easily replicated.

Organizational Efficiency Gains

The systematic approach delivered measurable improvements in how the organization functioned. Decision-making accelerated because data infrastructure made trade-offs visible. Resource conflicts that previously created organizational friction now resolved quickly through transparent prioritization systems.

The transformation demonstrated that systematic product management principles, when properly adapted to state enterprise constraints, can deliver results even under intense public accountability pressure and immovable deadlines.

Framework Development: Refinement Through State Enterprise Application

Key Learnings Refined Into Framework

State Enterprise Adaptation Patterns: This transformation refined understanding of how systematic product management adapts to state-owned enterprise contexts:

Public Accountability Pressure: Immovable deadlines created by public commitments (logistics center opening, infrastructure expansion announcements) require even more rigorous systematic coordination than private sector urgency. The transparency provided by data infrastructure proved essential for maintaining stakeholder confidence during complex transformation.

Stakeholder Complexity: Government ownership, regulatory oversight, public interest considerations, and competitive market dynamics create stakeholder webs requiring transparent systematic management. Data visualization tools helped communicate progress and trade-offs across this complex stakeholder landscape.

Procurement Constraints: Traditional public sector procurement processes can throttle agility. The framework refined to include innovative approaches navigating regulatory requirements while enabling iterative development.

Culture Change in Bureaucratic Contexts: State enterprises often have deeply embedded hierarchical decision-making patterns. Systematic transformation requires respecting institutional context while introducing new coordination mechanisms. Data-driven transparency helped shift decision-making from opinion-based to evidence-based without directly challenging organizational hierarchy.

Organizational Design Refinement

Product Office Structure: Omniva validated the Product Office as organizational design pattern for transformation contexts. Key refinements:

- Dual reporting clarity: Product teams need clear accountability to product outcomes while maintaining functional expertise development

- Decision rights mapping: Explicit documentation of who decides what prevents coordination breakdowns under pressure

- Data accessibility: Product-driven organizations require systematic information flows—creating these infrastructures proved as important as team structures themselves

Cross-Functional Team Coordination: Managing parcel machine and sorting center development simultaneously refined understanding of how product teams coordinate when outcomes require integration:

- Interface definition discipline: Clear contracts between teams prevent integration chaos

- Shared technical governance: Technology Panel-style structures enable architectural consistency without centralized bottlenecks

- Iterative integration: Rather than "big bang" system integration, systematic incremental verification prevents late-discovered conflicts

Risk Management Pattern Validation

Incremental Delivery Under Fixed Deadlines: The logistics center constraint (immovable opening date with concrete already poured) provided extreme test case for iterative delivery principles:

Validated Approach: Start with minimal viable functionality enabling core operations, then enhance systematically based on real operational feedback. This proved more reliable than comprehensive upfront specification under deadline pressure.

Counter-intuitive Insight: Iterative delivery feels slower initially (first increments may have less functionality than traditional approaches would deliver in first release). But systematic validation and course correction enables higher confidence in meeting critical deadlines.

Vendor Independence Pattern

Strategic Autonomy Through Capability Building: Breaking parcel machine vendor lock-in provided case study in systematic approach to strategic independence:

Pattern: Identify specific capability creating strategic constraint → Build minimal internal expertise enabling autonomous evolution → Iterate toward competitive advantage rather than perfect initial solution

Refinement: This pattern applies beyond technology. Any area where vendor dependency constrains strategic options becomes candidate for systematic capability building.

Data Infrastructure Pattern Development

Data Products for Internal Coordination: The visual management platform approach refined understanding of data infrastructure as organizational capability:

Pattern: Treat management information as product serving internal customers → Design for usability and strategic alignment → Reorganize processes to generate quality data → Use transparency to drive evidence-based decisions

Key Insight: Data infrastructure isn't just technical implementation—it requires workflow transformation so information flows naturally through systematic processes. The dashboard was successful not because of technology, but because we reorganized how work was tracked and reported.

Application: This pattern proved particularly valuable in bureaucratic contexts where hierarchical opinion traditionally dominated decision-making. Data transparency enabled evidence-based discussions without directly challenging organizational authority structures.

Transferable Patterns for Complex Organizational Transformation

Framework Elements Validated

Product Office Organizational Design: Cross-functional product teams enable agility while respecting institutional structures when implemented with dual reporting clarity and explicit decision rights.

Incremental Delivery Under Fixed Deadlines: Counter-intuitively, iterative approaches provide higher confidence for immovable deadlines than comprehensive upfront planning.

Strategic Vendor Independence: Systematic capability building in areas of vendor dependency creates long-term strategic autonomy and competitive advantage.

Data-Driven Culture Shift: Moving from hierarchical opinion to systematic evidence gathering transforms decision quality in bureaucratic contexts. Building data infrastructure that makes organizational reality visible enables evidence-based prioritization.

Measurement as Coordination Tool: Data products designed for internal customers enable systematic coordination across complex initiatives. Transparency forces realistic resource allocation and prevents hidden organizational bottlenecks.

Technical Context

Organization: Omniva (State-owned postal and logistics enterprise)

Transformation Scope: Technology stack replacement (parcel machines, sorting, courier systems, geoinformation), organizational transformation from project-driven to product-driven management

Critical Deliverables: New logistics center opening (immovable deadline), proprietary parcel machine production launch, new information system implementation with legacy system shutdown

Team Structure: Product Office creation, cross-functional product teams, dual PM role on critical initiatives, Technology Panel for architectural coordination

Data Infrastructure: Visual management dashboard, IT bottleneck tracking, resource allocation transparency, strategic alignment visibility

Outcomes: On-schedule delivery, vendor independence achieved, hundreds of new parcel machines deployed, market position maintained during transformation

Framework Application: Systematic product management principles adapted to state enterprise context with public accountability pressures